22DH-A10 Poppet 2-Txoj Kev NC Solenoid Valve

Cov yam ntxwv ntawm cov khoom

1. Cov kauj vuam uas ua haujlwm tas mus li.

2. Lub rooj zaum tawv rau lub neej ntev thiab xau tsawg.

3. Cov hluav taws xob thiab cov kev xaus ntawm lub kauj xaiv tau.

4. Kev tsim kho cov cuab yeej ntub dej zoo.

5. Cov cartridges yog qhov voltage sib pauv tau.

6. Kev xaiv hloov pauv tes.

7. Xaiv tau cov E-Coils uas tsis muaj dej tsis nkag uas ntsuas tau txog IP69K.

8. Kev tsim qauv sib xyaw ua ke, pwm pwm.

9. Kev lag luam feem ntau qhov kab noj hniav.

Cov Lus Qhia Txog Khoom

| Qauv Khoom | 22DH-A10 Poppet 2-Txoj Kev NC Solenoid Valve |

| Kev Ua Haujlwm Siab | 207 bar (3000 psi) |

| Pov thawj siab | 350 bar (5100 psi) |

| Kev Xaus Sab Hauv | 0.15 ml/feeb (3 tee/feeb) siab tshaj plaws ntawm 207 bar (3000 psi) |

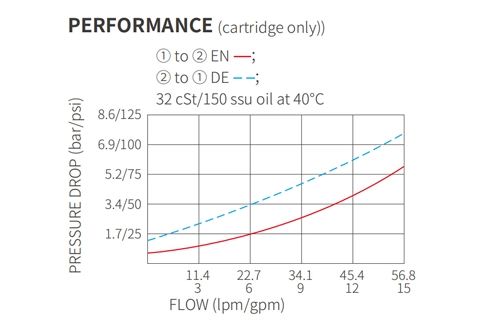

| Ntws | Saib Daim Ntawv Qhia Kev Ua Tau Zoo |

| Kub | -40°℃~100°C |

| Kev Ntsuas Lub Luag Haujlwm ntawm Coil | Txuas ntxiv mus ntawm 85% mus rau 115% ntawm lub zog nominal |

| Lub Sijhawm Teb | Qhov qhia thawj zaug ntawm kev hloov pauv ntawm lub xeev nrog 100% voltage muab rau ntawm |

| 80% ntawm qhov ntsuas nominal: | |

| Muaj zog: 40 msec.; Tsis muaj zog: 32 msec. | |

| Pib Lub Kauj Tam Sim No Kos Ntawm 20 ° C | Pib Lub Kauj Tam Sim No Kos Ntawm 20 ° C |

| Qhov Hluav Taws Xob Tsawg Kawg Nkaus | Qhov qhia thawj zaug ntawm kev hloov pauv ntawm lub xeev nrog 100% voltage muab rau ntawm |

| 80% ntawm qhov ntsuas kev ntws nominal: Muaj zog: 40 msec; Tsis muaj zog: 32 msec. | |

| Cov kua dej | Cov khoom siv ua los ntawm cov ntxhia los yog cov khoom siv hluavtaws uas muaj cov khoom siv lubricating ntawm viscosities ntawm 7.4 txog 420 cSt (50 txog 2000 ssu). |

| Kev teeb tsa | Tsis muaj kev txwv |

| Lub thawv | Qhov hnyav: 0.16 kg. (0.35 lbs.); Hlau nrog cov chaw ua haujlwm tawv. Cov chaw uas raug zinc plated |

| Lub foob | D hom foob nplhaib |

| Lub cev txheem Ported | Qhov hnyav: 0.16 kg. (0.35 lbs.); Anodized muaj zog heev 6061 |

| T6 txhuas alloy, ntsuas rau 240 bar (3500 psi). | |

| Muaj cov hlau ductile thiab steel lub cev; qhov loj me yuav txawv. | |

| Txheej Txheem Coil | Qhov hnyav: 0.27 kg. (0.60 lbs.); Cov thermoplastic uas tau muab tso rau hauv lub thawv kaw, |

| E-Coil | Chav Kawm H kub siab magnetwire. Qhov hnyav: 0.41 kg. (0.9 lbs.); Qhov txhab zoo meej, puv nrog cov khoom siv ruaj khov plhaub hlau sab nraud; Ntsuas txog IP69K nrog cov khoom sib txuas ua ke. |

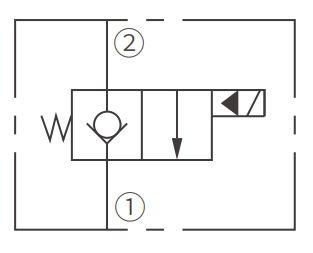

Lub Cim Ua Haujlwm ntawm Khoom

Thaum lub valve 22DH-A10 tsis muaj zog, nws ua haujlwm ua lub valve kuaj, tso cai rau dej ntws los ntawm qhov chaw ① mus rau qhov chaw ② thaum thaiv dej ntws los ntawm qhov chaw ② mus rau qhov chaw ①. Txawm li cas los xij, thaum lub valve muaj zog, lub poppet hauv lub valve core nce, qhib txoj kev ntws los ntawm qhov chaw ② mus rau qhov chaw ①. Hauv hom no, dej ntws los ntawm qhov chaw ① mus rau qhov chaw ② kuj raug tso cai. Lub valve muaj qhov ua haujlwm override tes rau kev tswj hwm kev ua haujlwm. Txhawm rau qhib override, nias lub pob thiab tig nws 180 ° counterclockwise, tom qab ntawd tso tawm. Hauv qhov chaw no, lub valve yuav tseem qhib tsis hais txog qhov xwm txheej fais fab. Txhawm rau rov qab mus rau kev ua haujlwm ib txwm, nias lub pob, tig nws 180 ° clockwise, thiab tso nws tawm. Hauv lub xeev no, qhov override yuav raug tso rau qhov chaw ruaj ntseg thiab lub valve yuav rov qab ua haujlwm ib txwm.

Kev Ua Tau Zoo/Qhov Ntev

VIM LI CAS THIAJ LI XAIV PEB

Peb ua haujlwm li cas

Kev loj hlob(qhia rau peb paub koj lub tshuab qauv lossis tsim)

Kev hais lus(peb yuav muab ib daim ntawv qhia nqe rau koj sai li sai tau)

Cov qauv(cov qauv yuav raug xa tuaj rau koj rau kev tshuaj xyuas zoo)

Kev txiav txim(muab tso tom qab paub meej tias muaj pes tsawg thiab lub sijhawm xa khoom, thiab lwm yam)

Tsim Qauv(rau koj cov khoom)

Kev tsim khoom(tsim cov khoom raws li cov neeg siv khoom xav tau)

QC(Peb pab pawg QC yuav tshuaj xyuas cov khoom thiab muab cov ntawv qhia QC)

Thauj khoom(thauj cov khoom uas twb muaj lawm rau hauv cov thawv rau cov neeg siv khoom)

Peb Daim Ntawv Pov Thawj

Kev Tswj Xyuas Zoo

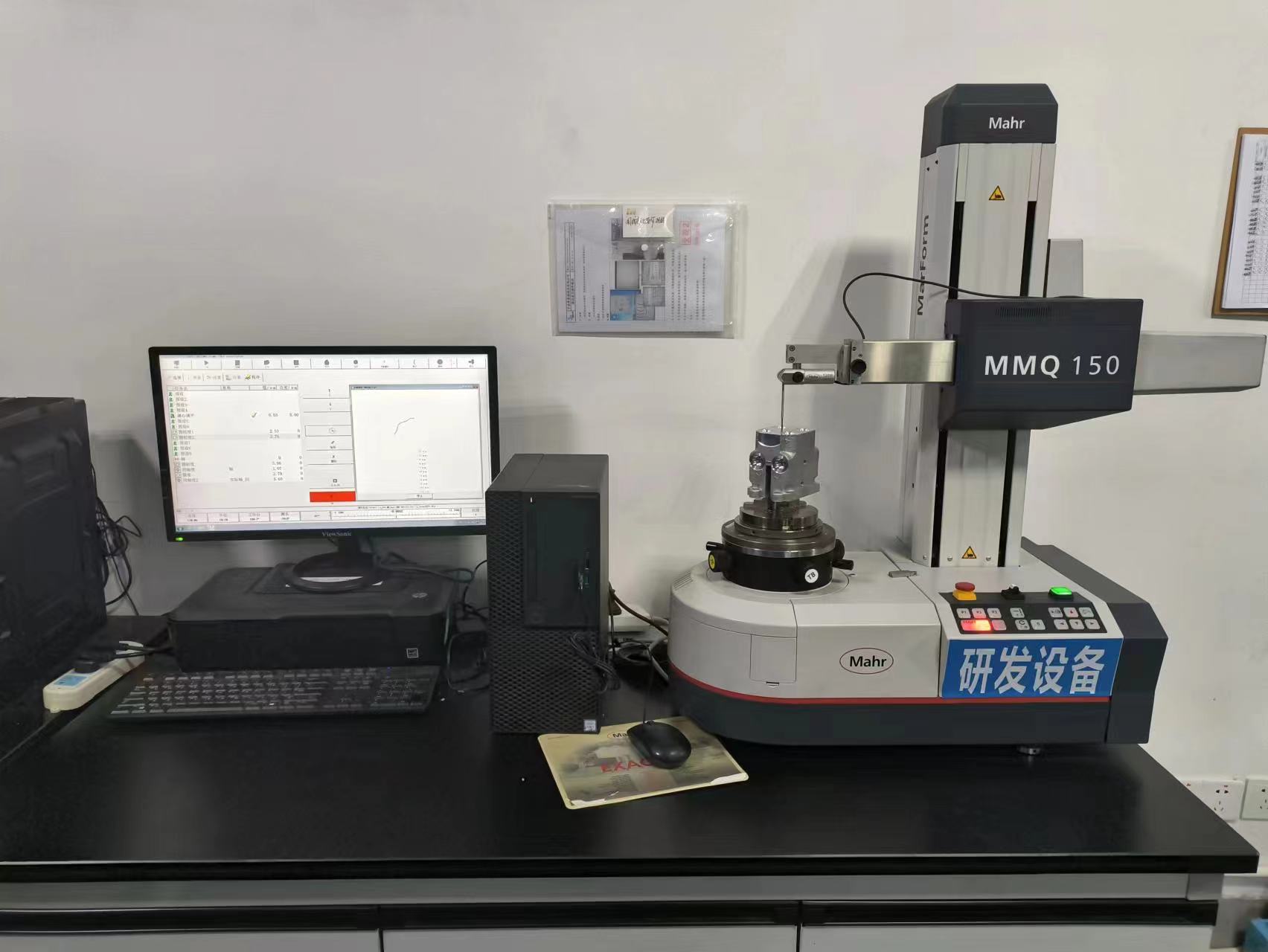

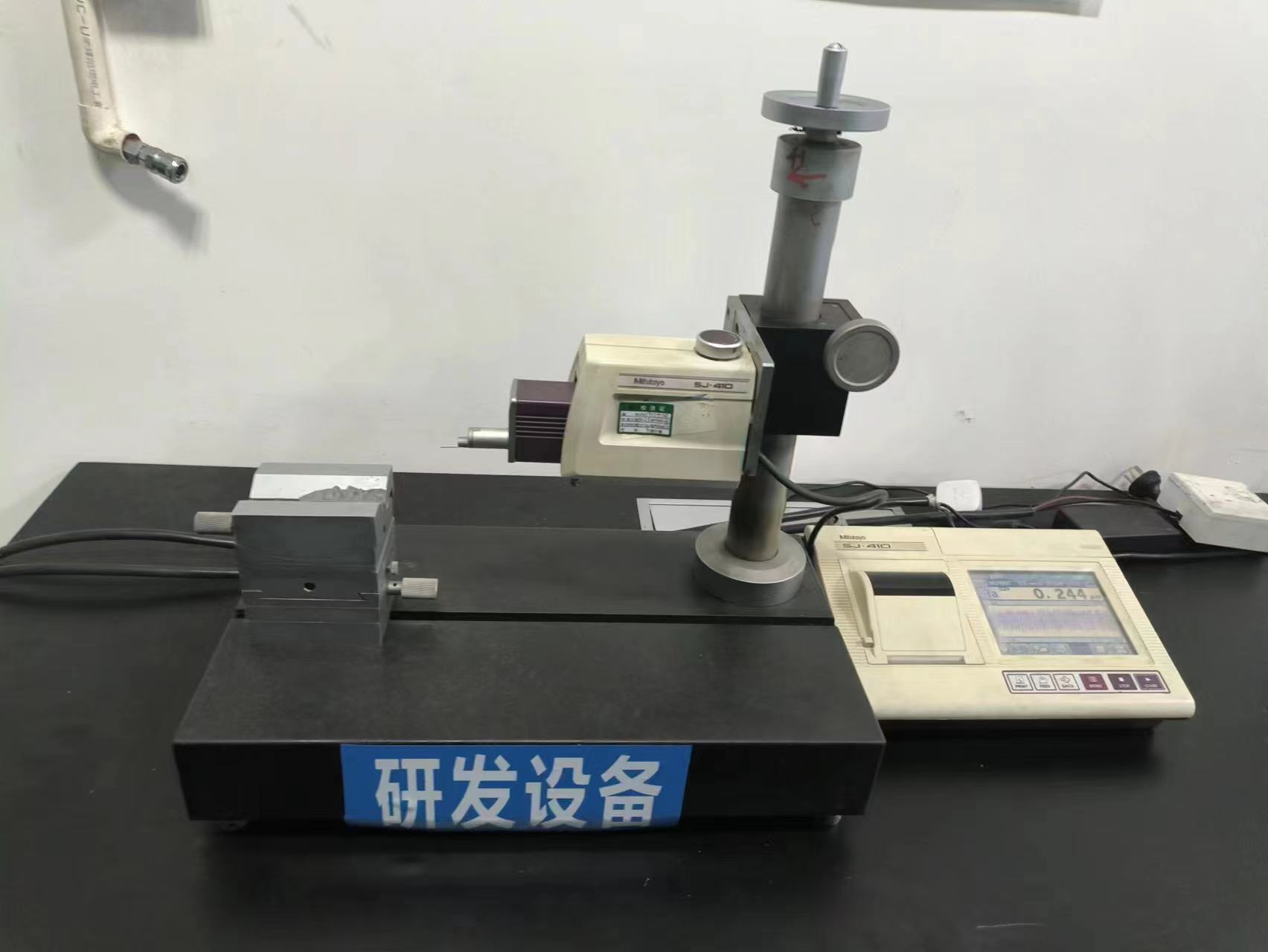

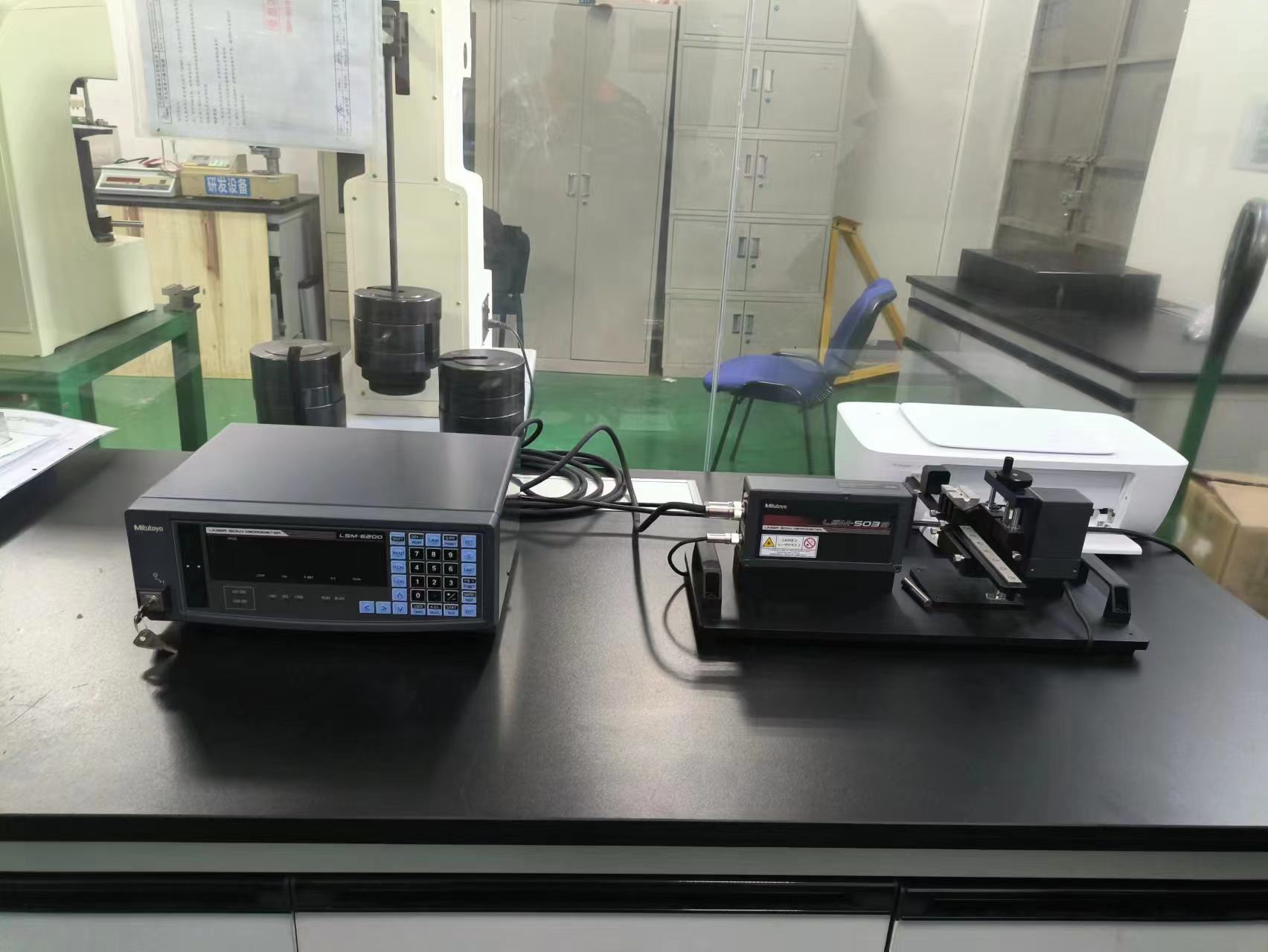

Yuav kom ntseeg tau tias cov khoom lag luam zoo, peb qhiaCov cuab yeej siv los ntxuav thiab kuaj cov khoom siv siab heev, 100% ntawm cov khoom sib dhos dhau qhov kev kuaj xyuas Hoobkasthiab cov ntaub ntawv xeem ntawm txhua yam khoom raug khaws cia rau ntawm lub computer server.

Pab pawg tshawb fawb thiab kev txhim kho

Peb pab pawg R & D muaj cov10-20cov neeg, feem ntau ntawm lawv muaj txog10 xyoontawm kev paub ua haujlwm.

Peb lub chaw R&D muaj ib qhoCov txheej txheem R&D zoo, suav nrog kev soj ntsuam cov neeg siv khoom, kev tshawb fawb txog kev sib tw, thiab kev tswj hwm kev lag luam.

Peb muajcov khoom siv R & D laussuav nrog kev xam qauv tsim, kev sim ua qauv ntawm lub tshuab tswj hwm, kev sim ua qauv hydraulic, kev debugging ntawm qhov chaw, chaw kuaj khoom, thiab kev tshuaj xyuas cov khoom siv finite.