Kev siv hluav taws xob mining winch, kev siv hluav taws xob mining windlass

Cov Lus Qhia Txog Khoom

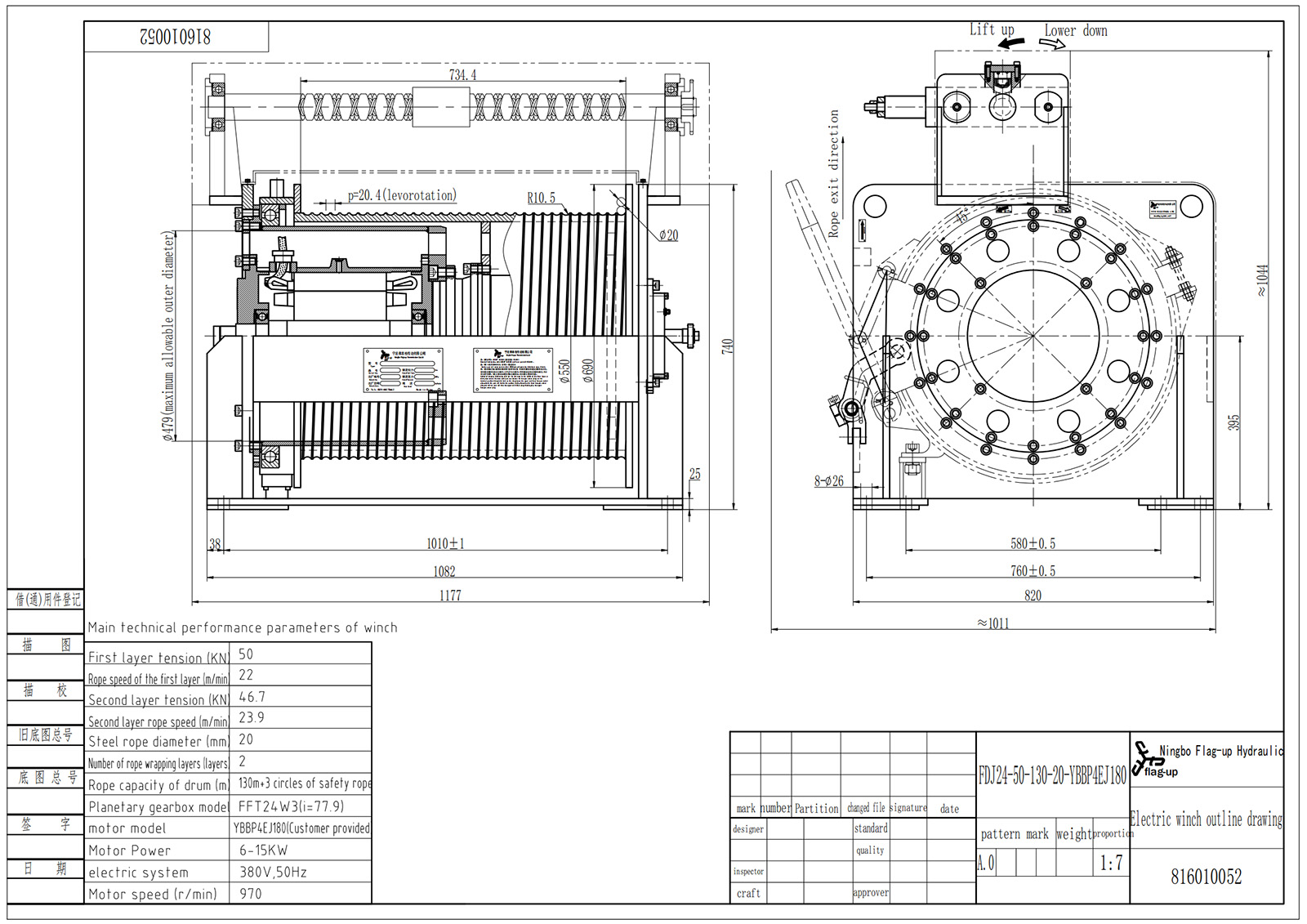

| Cov kev ua tau zoo tseem ceeb ntawm winch | |

| Thawj txheej nruj (KN) | 50 |

| Qhov ceev ntawm thawj txheej (m/min) | 22 |

| Qhov nro txheej thib ob (KN) | 46.7 |

| Qhov ceev ntawm txoj hlua txheej thib ob (m/min) | 23.9 |

| Txoj hlua hlau txoj kab uas hla (hli) | 20 |

| Tus naj npawb ntawm cov hlua qhwv txheej (txheej) | 2 |

| Lub peev xwm ntawm cov hlua (m) | 130m + 3 lub voj voog ntawm txoj hlua kev nyab xeeb |

| Qauv gearbox planetary | FFT24W3(i = 77.9) |

| Qauv tsav tsheb | YBBP4EJ180 (Cov neeg siv khoom muab) |

| Lub zog tsav tsheb | 6-15KW |

| Lub tshuab hluav taws xob | 380V, 50Hz |

| Lub cev muaj zog ceev (r/min) | 970 |

Cov yam ntxwv ntawm cov khoom

Cov winches hluav taws xob mining muaj cov yam ntxwv hauv qab no:

Muaj Peev Xwm Thauj Khoom Siab:Cov winches hluav taws xob feem ntau muaj lub peev xwm loj, uas tuaj yeem hloov kho rau qhov xav tau ntawm cov khoom hnyav hauv kev ua haujlwm tsuas.

Lub zog muaj zog:Nws siv lub cev muaj zog hluav taws xob ua lub zog thiab muaj zog tso zis, uas tuaj yeem muab lub zog torque thiab qhov ceev txaus los hloov kho rau ntau yam kev xav tau ua haujlwm.

Kev Ua Haujlwm Zoo:Cov winches hluav taws xob mining siv lub kaw lus kis tau tsim los ntawm kev tshaj lij, uas muaj kev ua haujlwm kis tau zoo thiab tuaj yeem nqa thiab thauj cov khoom hnyav sai sai, txhim kho kev ua haujlwm zoo.

Muaj Kev Nyab Xeeb Thiab Txhim Khu Kev Ntseeg Tau:Cov winches hluav taws xob tsuas yog feem ntau nruab nrog ntau yam khoom siv tiv thaiv kev nyab xeeb, xws li cov hloov pauv txwv, cov khoom siv tiv thaiv overload, thiab lwm yam, kom ntseeg tau tias muaj kev nyab xeeb ntawm cov khoom siv thiab cov neeg teb xov tooj.

Muaj zog ruaj khov:Cov winches hluav taws xob mining siv cov ntaub ntawv muaj zog thiab cov txheej txheem tsim khoom tshaj lij, uas muaj kev ruaj khov zoo thiab tiv taus huab cua, thiab tuaj yeem tswj tau kev ruaj khov thiab kev siv tau ntev txawm tias nyob hauv qhov chaw ua haujlwm mining hnyav.

Daim Ntawv Thov

Cov winches hluav taws xob tsuas yog siv dav hauv kev tsa thiab tuav haujlwm hauv cov chaw tsuas, xws li cov chaw tsuas thee, cov chaw tsuas hlau, thiab cov chaw zeb.

Kev kos duab

VIM LI CAS THIAJ LI XAIV PEB

Peb ua haujlwm li cas

Kev loj hlob(qhia rau peb paub koj lub tshuab qauv lossis tsim)

Kev hais lus(peb yuav muab ib daim ntawv qhia nqe rau koj sai li sai tau)

Cov qauv(cov qauv yuav raug xa tuaj rau koj rau kev tshuaj xyuas zoo)

Kev txiav txim(muab tso tom qab paub meej tias muaj pes tsawg thiab lub sijhawm xa khoom, thiab lwm yam)

Tsim Qauv(rau koj cov khoom)

Kev tsim khoom(tsim cov khoom raws li cov neeg siv khoom xav tau)

QC(Peb pab pawg QC yuav tshuaj xyuas cov khoom thiab muab cov ntawv qhia QC)

Thauj khoom(thauj cov khoom uas twb muaj lawm rau hauv cov thawv rau cov neeg siv khoom)

Peb Daim Ntawv Pov Thawj

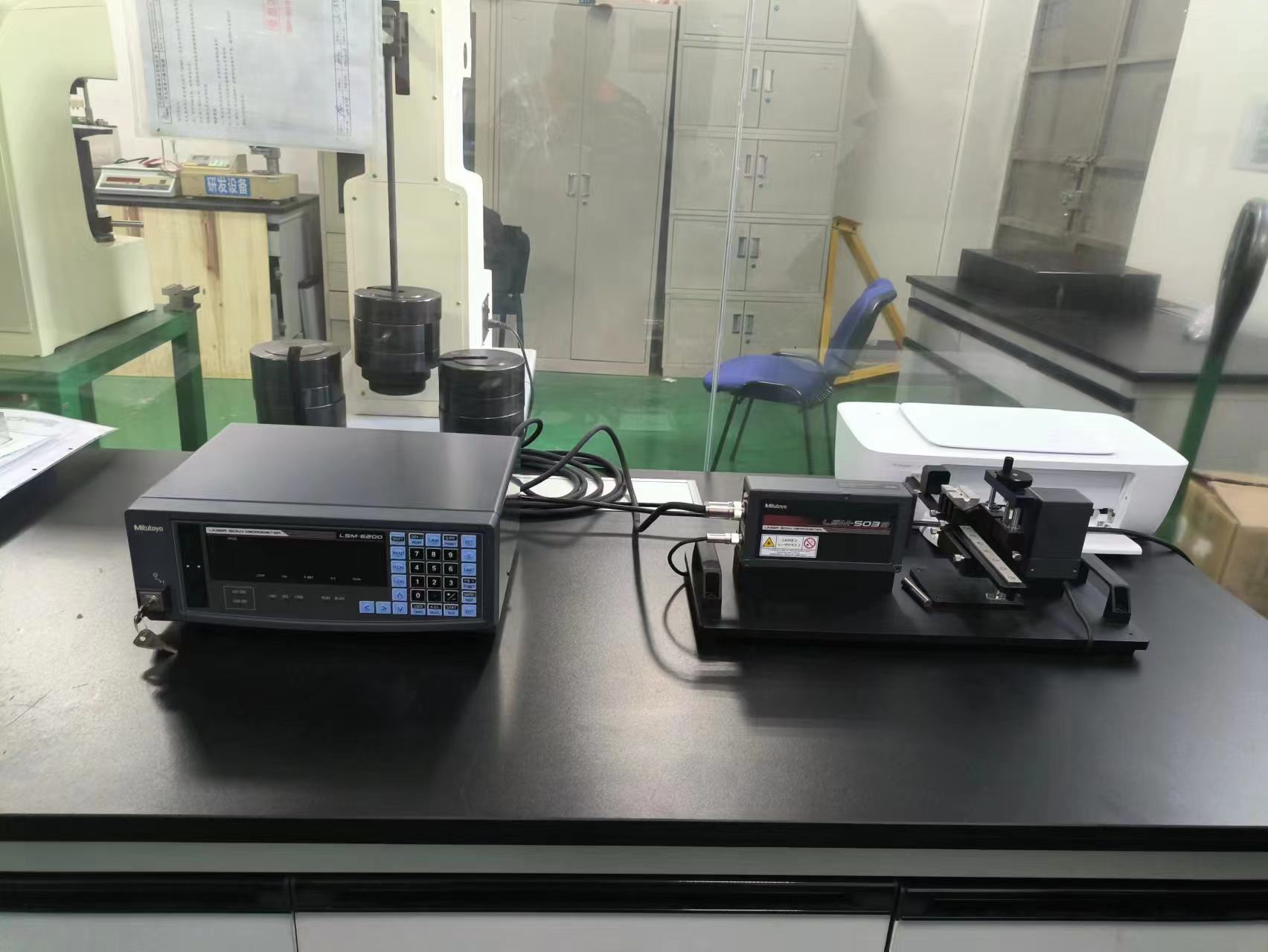

Kev Tswj Xyuas Zoo

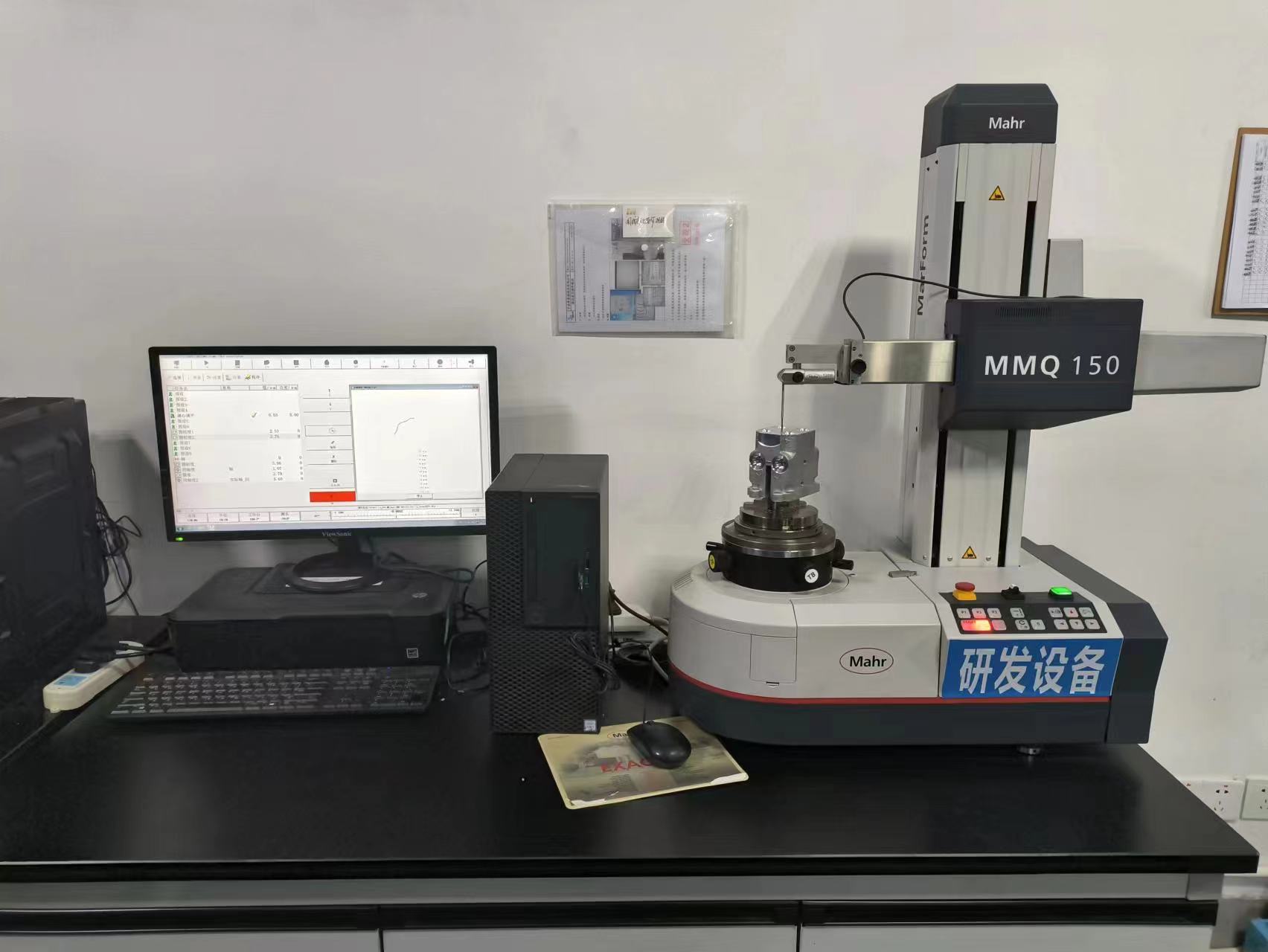

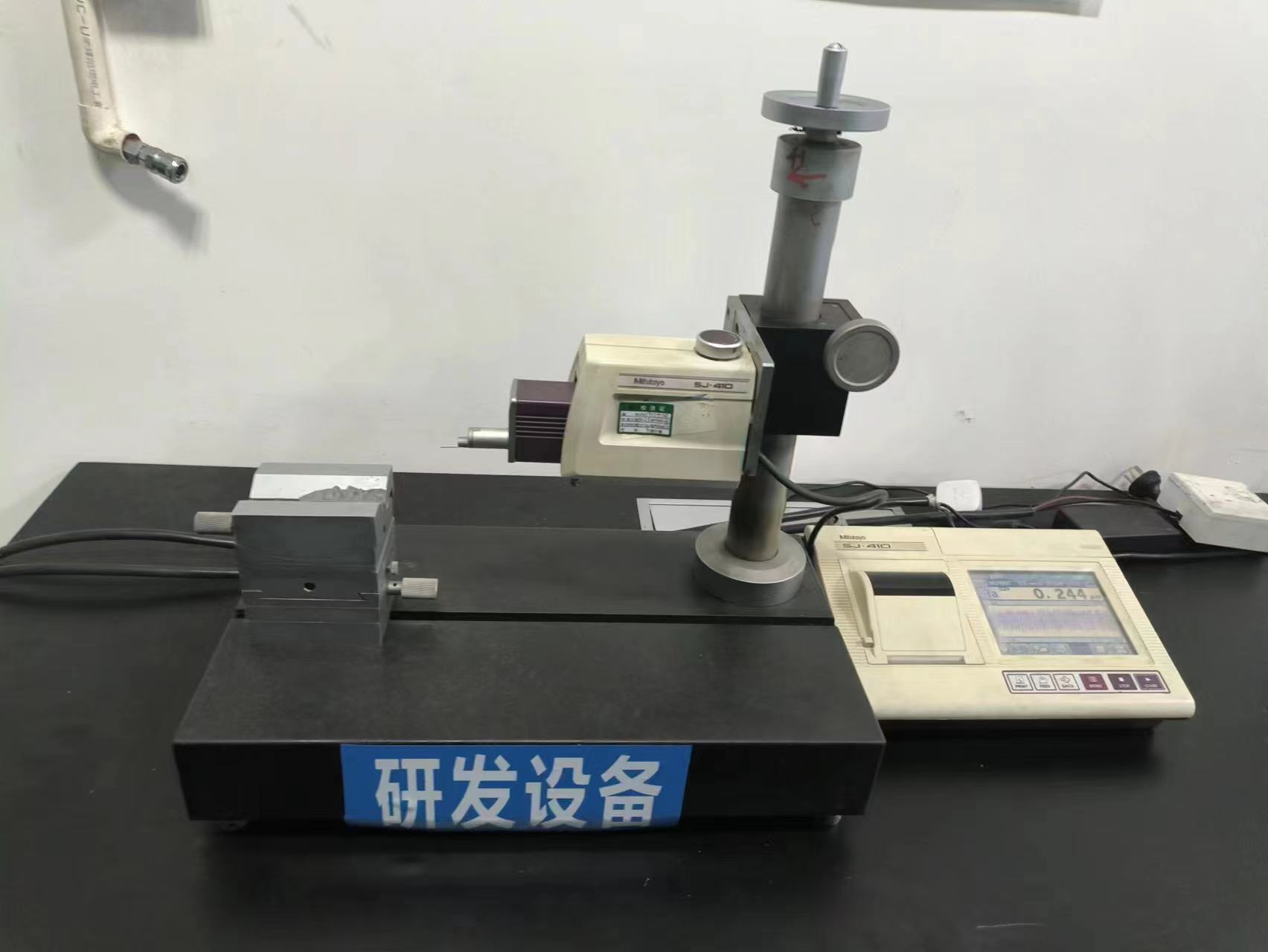

Yuav kom ntseeg tau tias cov khoom lag luam zoo, peb qhiaCov cuab yeej siv los ntxuav thiab kuaj cov khoom siv siab heev, 100% ntawm cov khoom sib dhos dhau qhov kev kuaj xyuas Hoobkasthiab cov ntaub ntawv xeem ntawm txhua yam khoom raug khaws cia rau ntawm lub computer server.

Pab pawg tshawb fawb thiab kev txhim kho

Peb pab pawg R & D muaj cov10-20cov neeg, feem ntau ntawm lawv muaj txog10 xyoontawm kev paub ua haujlwm.

Peb lub chaw R&D muaj ib qhoCov txheej txheem R&D zoo, suav nrog kev soj ntsuam cov neeg siv khoom, kev tshawb fawb txog kev sib tw, thiab kev tswj hwm kev lag luam.

Peb muajcov khoom siv R & D laussuav nrog kev xam qauv tsim, kev sim ua qauv ntawm lub tshuab tswj hwm, kev sim ua qauv hydraulic, kev debugging ntawm qhov chaw, chaw kuaj khoom, thiab kev tshuaj xyuas cov khoom siv finite.

-

Kev siv hluav taws xob mining winch, kev siv hluav taws xob mining windlass

Kev siv hluav taws xob mining winch, kev siv hluav taws xob mining windlass